Intelligent technology for top quality and productivity

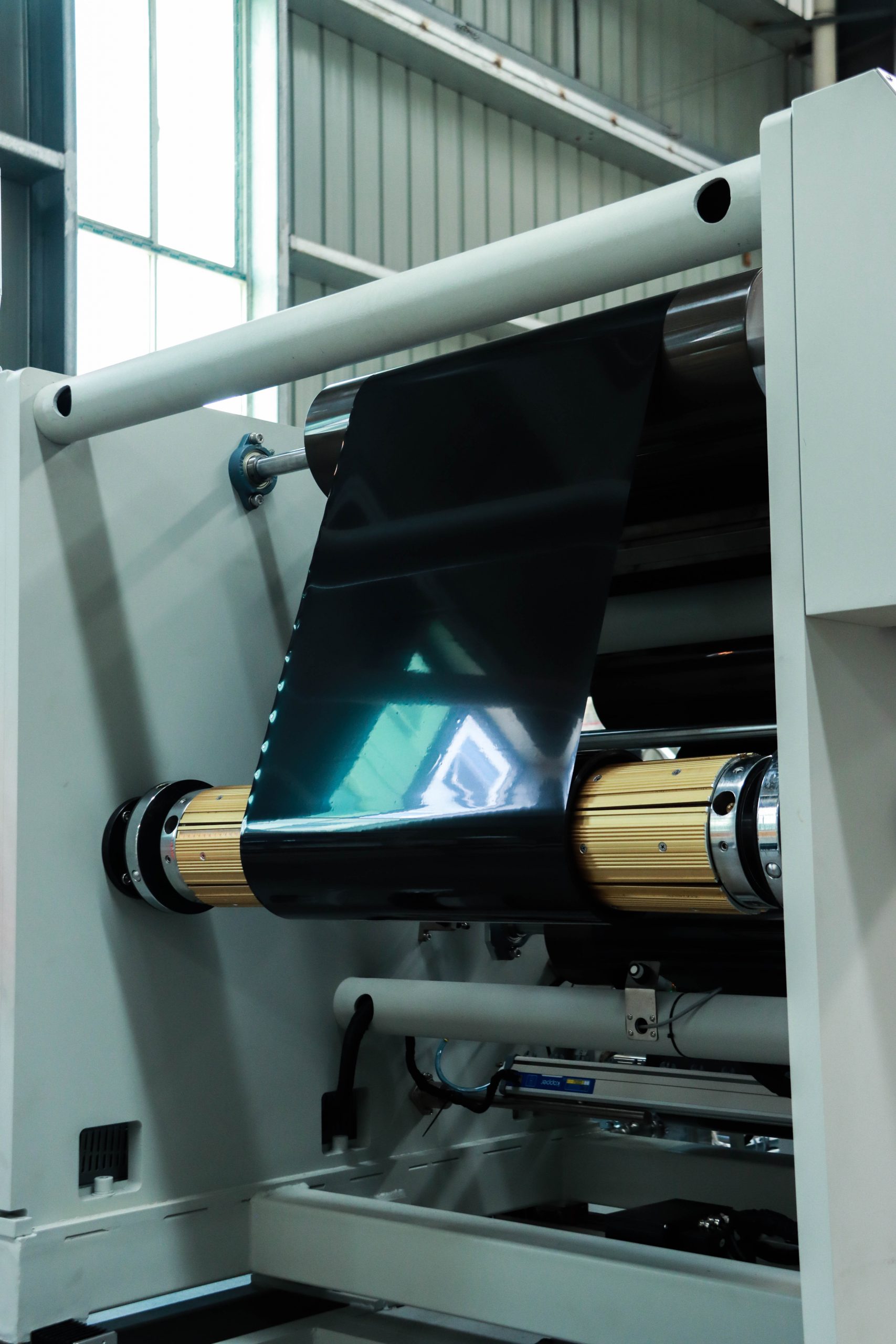

The hydraulic isostatic double steel belts press is an advanced equipment that combines hydraulic technology and isostatic pressure principle. The steel belt not only transfers pressure, but also transfers heat to the material through its thermal conductivity, achieving material forming under high temperature and high pressure environment.

Adopting a double steel belts design, continuous feeding and discharging of materials can be achieved, greatly improving production efficiency. Pressure and temperature can be precisely controlled to ensure optimal performance, meeting the needs of various applications. We pays attention to energy conservation and environmental protection in the design and manufacturing process, reducing energy consumption and carbon emissions.

Product Detail

Using oil pressure isostatic pressure technology, pressure fluctuation ±2%;

Using oil direct heating technology, temperature fluctuation ±3℃;

Heating pressure cooling system standardized configuration, compact production line structure, quickly flexible to adapt to customer sites.

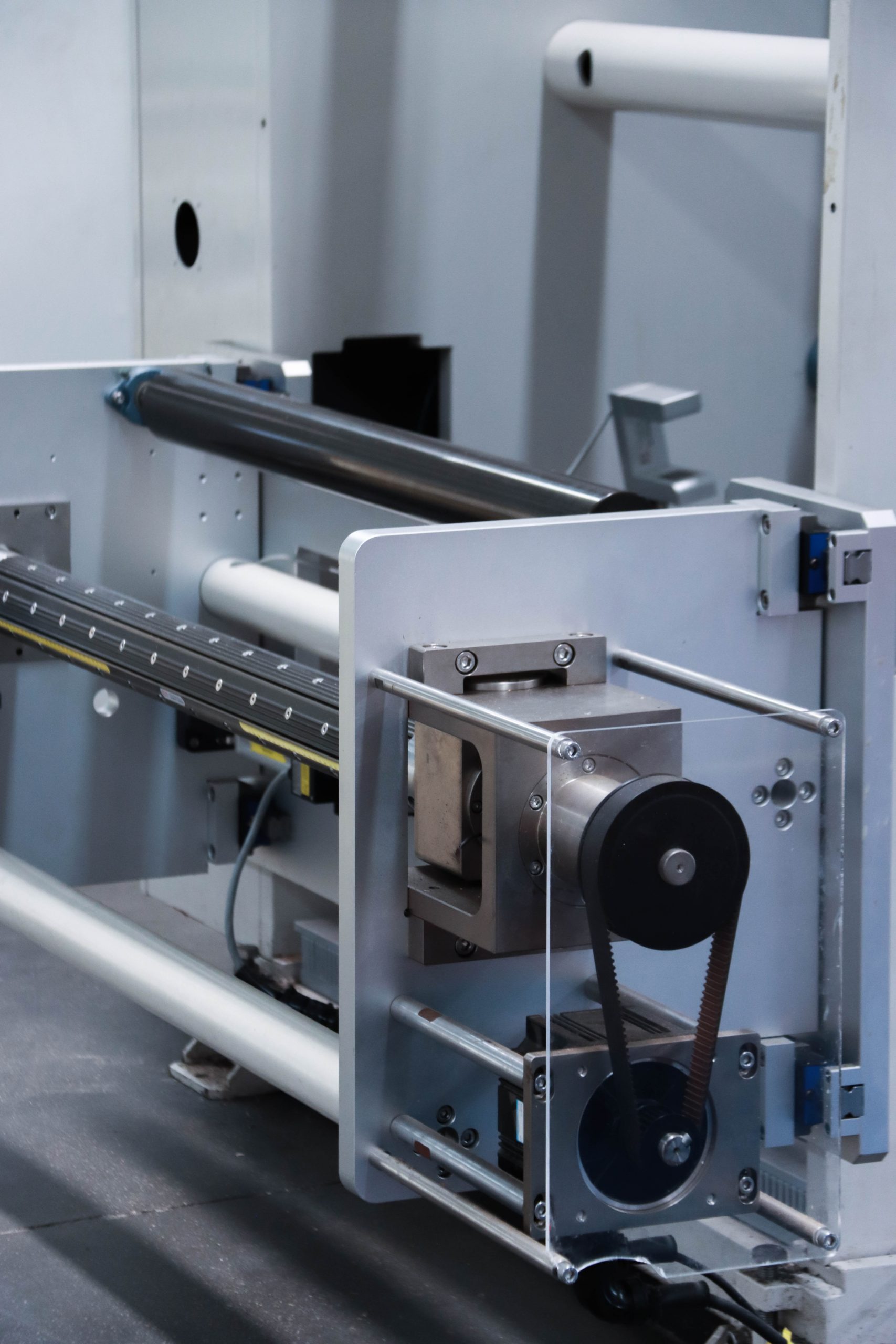

Adopt modular structure design; Hot pressing module, cooling module can be modular configuration, can also be non-standard to adapt to complex process configuration;

The automatic lifting technology of pressure plate or upper module can be quickly adjusted to adapt to the thickness of the product.

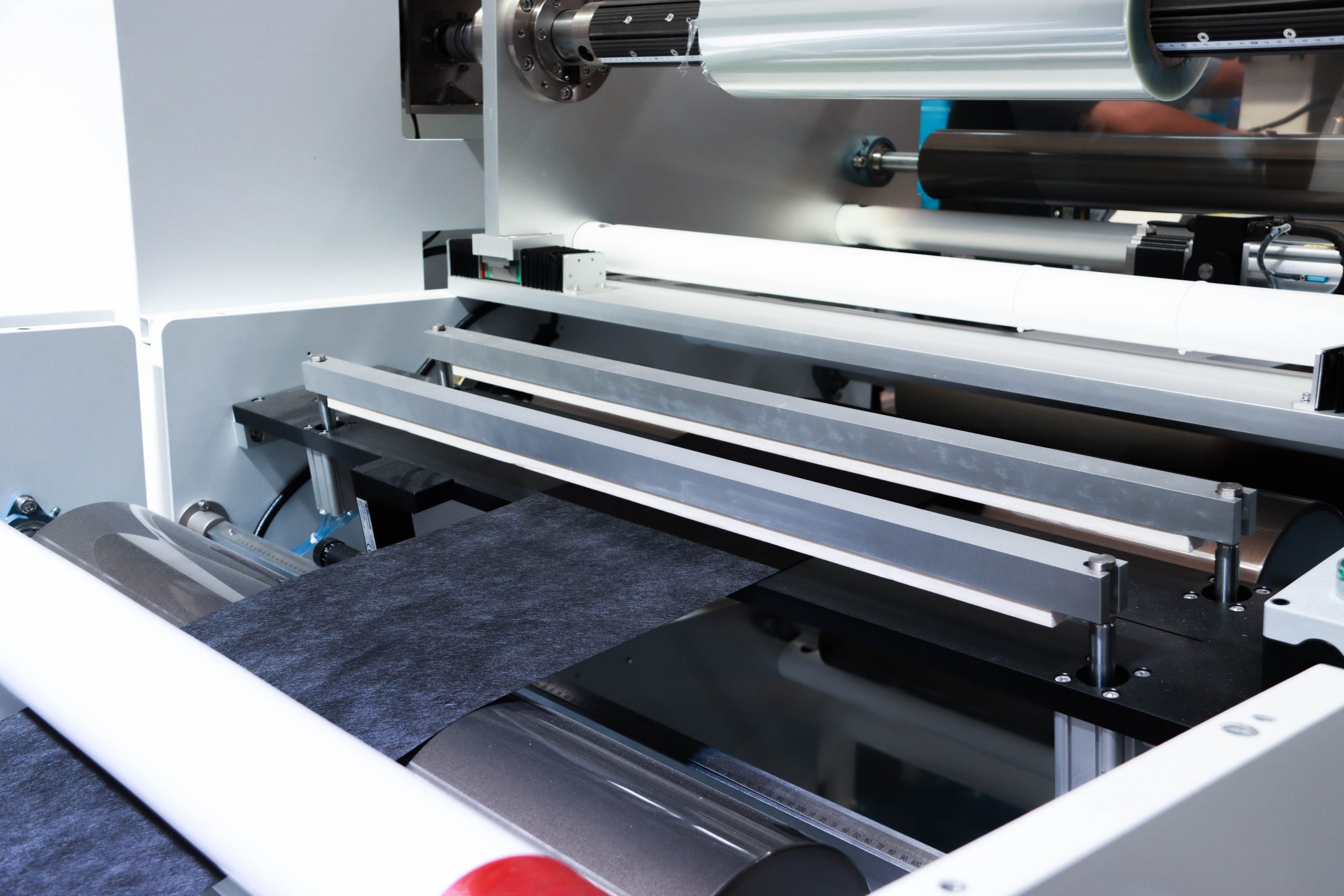

Equipment for continuous operation of press equipment

Unwinding system

Unwinding drive system: The unwinding reel is an inflatable shaft cantilever structure (3-inch shaft), a total of 12, the maximum winding diameter Φ800mm, the maximum bearing capacity 120kg. Servo motor drive.

Correction system: A total of 12 groups, the correction system adopts ultrasonic sensor for correction, resolution 0.01mm, correction accuracy < ±1mm.

Tension control system: a total of 12 groups, using servo motor torque mode to control tension, tension control size 0~20 N, tension control accuracy ±5 N

Winding system

With drive, tension control, edge cutting and electrostatic elimination devices.

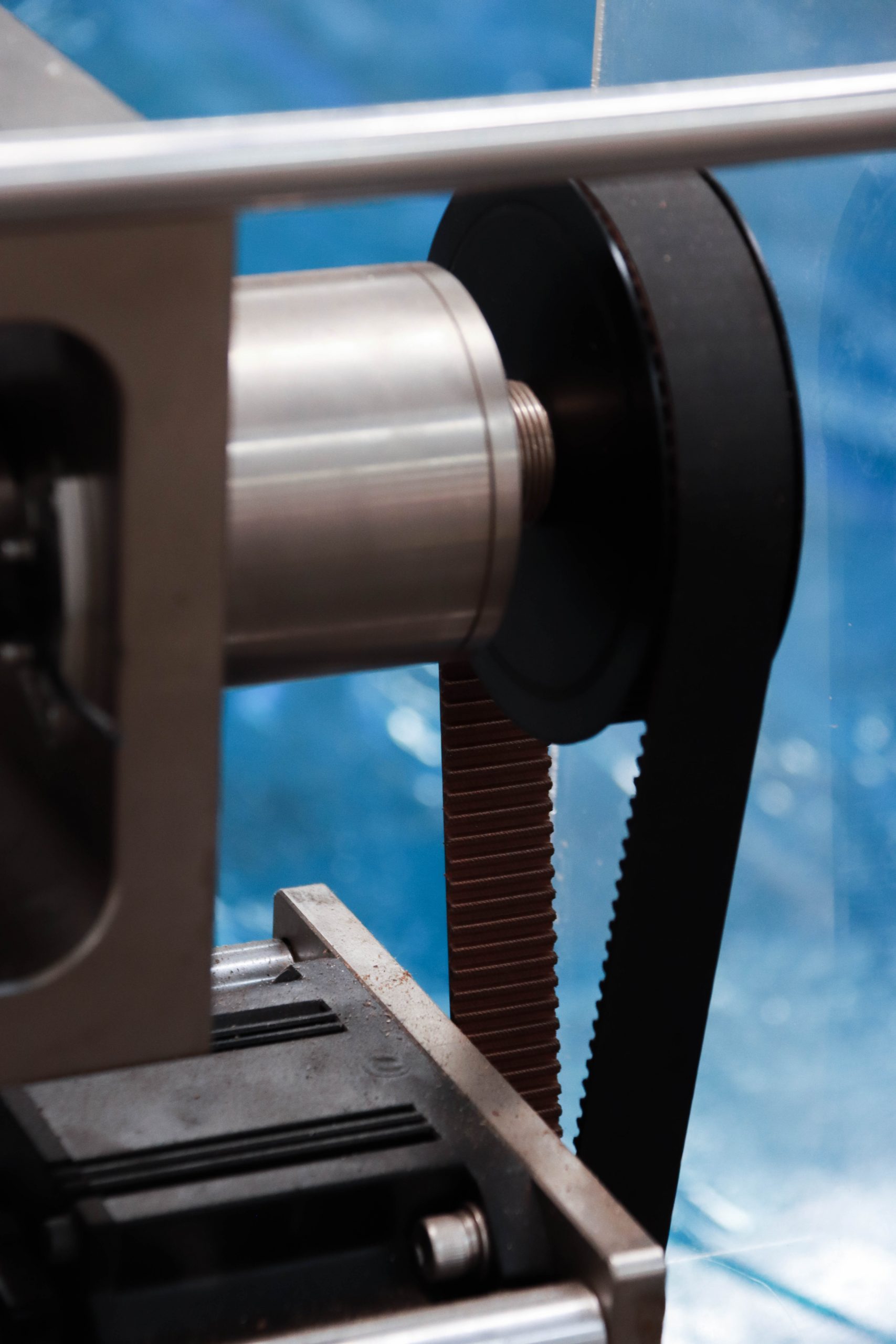

Cutting system

The parallelism and perpendicularity of the cross-cutting device and the longitudinal cutting device are used to evaluate whether the two sides of the cut material are parallel and whether it is perpendicular to the strip axis。

Technical Data

Incoming material width 0-1200mm, incoming material thickness 0-1mm

The temperature after hot pressing is ±10μm, and the temperature of preheating zone is RT-250℃

The length of the hot pressing area is N*1000mm, and the length of the cold pressing area is N*1000mm

The maximum temperature of hot pressing zone is 250℃, and the temperature of cooling zone is RT-100℃

Isostatic pressure 0.1Mpa-2Mpa

Steel strip speed 0.1m/min-5m/min

Compelling justifications for selecting LSD

01.

Leading hydraulic technology and sustainable innovating

01. Leading hydraulic technology and sustainable innovating

Learn more02.

Excellent reliability

02. Excellent reliability

Learn more03.

Unreserved services